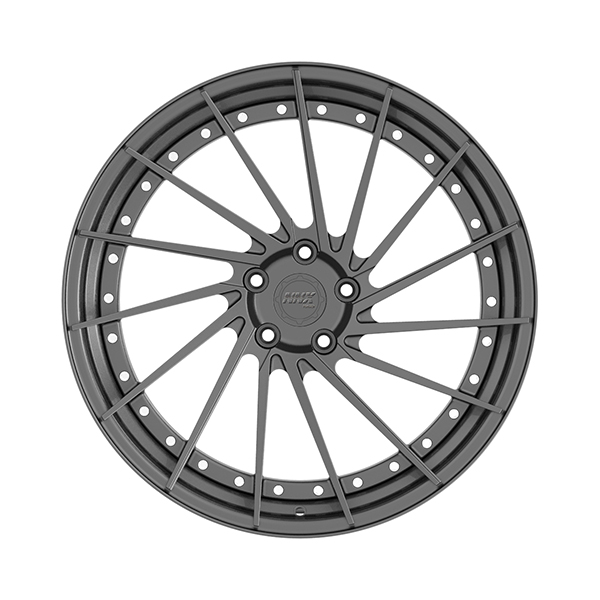

New Design Customizable Wheels On The Car 18 Inches Car Alloy Rims 5X112 22 Inch Forged car wheels

| Size | Width | ET(Offset) | Center bore (hub bore) |

Bolt Pattern(PCD) | |||

| 18 | 7.5J/8J/8.5J/9J/9.5J/10J/10.5J/11J/12J | You can customize any data and color you need. | |||||

| 19 | 8.5J/9J/9.5J/10J/10.5J/11J | ||||||

| 20 | 8.5J/9J/9.5J/10J/10.5J/11J/12J | ||||||

| 21 | 8.5J/9J/9.5J/10J/10.5J/11J/12J | ||||||

| 22 | 8.5J/9J/9.5J/10J/10.5J/11J/12J/14J | ||||||

| 24 | 9.5J/10J/10.5J/11J/12J | ||||||

Itself has a lighter weight and better the dynamic balance of performance, so the more lightweight, higher reliability, higher in sealing; At the same time is a higher manufacturing costs, relative to a single simple modeling.

Forging hub is now the most advanced manufacturing aluminium wheel method. Forging hub has the advantage of high strength, higher security, high plasticity, light weight, good heat dissipation, fuel efficient, better control performance. As shown below: 1. Durable and more secure. The strength of the forging aluminum ring more than 1 to 2 times the cast aluminum ring, four to five times higher than ordinary iron ring. More solid, collision resistant, toughness and fatigue strength is superior to the casting wheel hub. Not easy rolling breakage and safer.

32 color combinations available in our online store.

The Hybrid Forged Billet Sport Cap offers 32 combinations of colors to personalize your NNX Wheels. Starting as 6061 billet aluminum, the cap bezels are machined, hand- finished and powder coated in Vossen’s Miami-based factory using the same finishes as NNX Forged wheels.