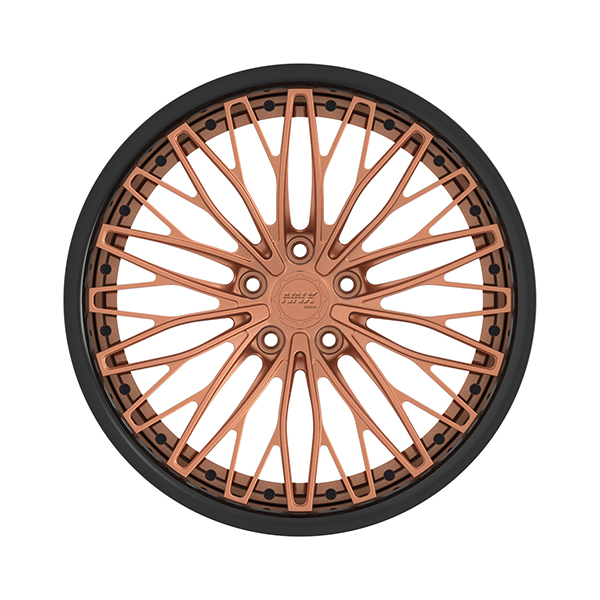

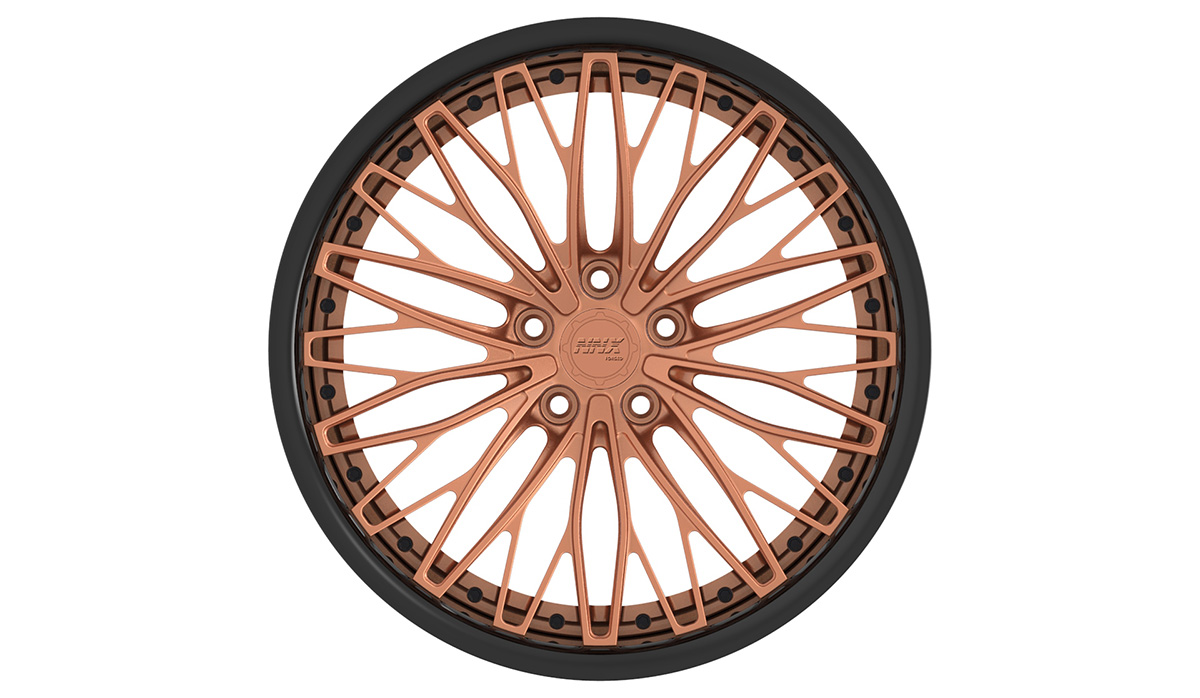

Customized 2 Piece Super Deep Concave Brushed Bronze Polished Lip Forged Wheels

| Size | Width | ET(Offset) | Center bore (hub bore) |

Bolt Pattern(PCD) | |||

| 18 | 7.5J/8J/8.5J/9J/9.5J/10J/10.5J/11J/12J | You can customize any data and color you need. | |||||

| 19 | 8.5J/9J/9.5J/10J/10.5J/11J | ||||||

| 20 | 8.5J/9J/9.5J/10J/10.5J/11J/12J | ||||||

| 21 | 8.5J/9J/9.5J/10J/10.5J/11J/12J | ||||||

| 22 | 8.5J/9J/9.5J/10J/10.5J/11J/12J/14J | ||||||

| 24 | 9.5J/10J/10.5J/11J/12J | ||||||

The only disadvantage is that the price is high and the manufacturing time is long. In addition, when the wheel hub is upgraded, the owner should not blindly choose the large wheels, and the design must have the weight of the wheels together. If you just upgrade the large -sized wheels for better design and increase the relative weight, it will definitely increase the fuel consumption of the vehicle.

It is also best to choose the wheels with relatively simple structural characteristics as much as possible. This wheel is very convenient and fast to clean. If it is a complicated wheel, it is likely to be refused to clean or raise it by the car beauty shop. 2 The difference between rotating wheels and forging wheels depends on cost, appearance and performance. In terms of cost, the technology of pressing the wheels is relatively simple, suitable for mass production, low cost, while forging wheels are complex and cost-high, but the performance is good. These two shapes are difficult to distinguish, but the characteristics of metal materials are very different. Forging wheels have stronger fatigue, impact resistance, and pressure resistance than rotary wheels. The quality of the rotation wheels heavier is about 20%compared with the forging wheel.

32 color combinations available in our online store.

The Hybrid Forged Billet Sport Cap offers 32 combinations of colors to personalize your NNX Wheels. Starting as 6061 billet aluminum, the cap bezels are machined, hand- finished and powder coated in Vossen’s Miami-based factory using the same finishes as NNX Forged wheels.