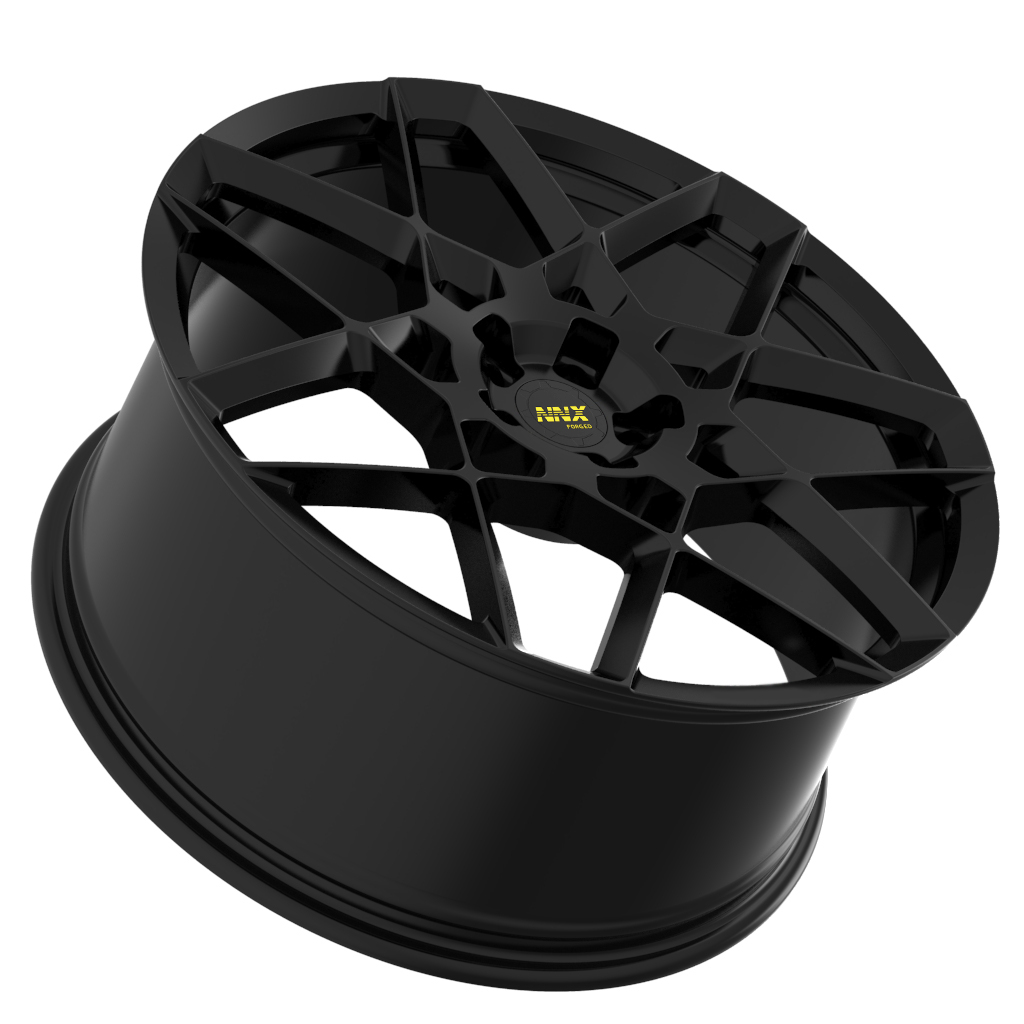

NNX-D912 22X10 ET 38 P.C.D 5X120 center hole 72.6 1piece forged wheel (custom 16-24inch any date)

Choice of gray material

The determination of roughness not only affects the economy of rough manufacturing, but also the economy of processing. Therefore, when determining Mao Yu, it is necessary to consider the factors of heat processing and the requirements of cold processing, and reduce the manufacturing cost of parts from the process of determining the link of Mao Yu.

In mechanical processing, there are many common hairy defects, and there are many manufacturing methods for the same hair defects. There are several common hair stools in mechanical manufacturing; castings, forgedings, profiles, welded parts, in addition, there are stamping parts and cold squeezing parts. Different types of wool injuries have different manufacturing and processing characteristics.

Complex-shaped parts should be made by casting. Most of the castings are cast in sand-shaped, divided into wood mold handmade shapes and metal molding shapes. Handmade wooden mold casting accuracy is low, the processing surface is large, the productivity is low, and it is suitable for the casting of a small or large parts of dry production. Metal machines have high productivity, high casting accuracy, but high equipment cost, limited weight of casting, suitable for mass production of small and medium-sized castings. Secondly, a small amount of small castings with high quality requirements can be cast (such as pressure casting, centrifugal manufacturing, and melting mold casting).

Due to the structure of the wheel hub, the windows of the wheels of the wheels are complicated, consisting of a variety of line types such as oblique planes, curves, and arcs. In addition, the overall shape structure of the wheels includes a physical structure such as arc-shaped bulge, inclined cylindrical cone surface, and weight loss pit. Therefore, the shape of the solid structure of the wheels is very complicated. Considering the complexity of its structure, the manufacturing method of the hair loss of the part should be used to use the Sichuan casting method in order to make the hair loss during the production process.

1. The question that should be considered when choosing a rough type

(1) Parts materials and their mechanical performance

The material of the component roughly determines the type of hair damage. For example, parts of the materials such as cast iron and bronze should be used as a blank casting: when the shape of the steel parts is not complicated and the mechanical properties are not too high, the profile can be selected. For important steel parts, in order to ensure its mechanical performance, you should choose to forge the blanks. Essence

(2) The structure and shape of the parts

Complex-shaped rough is generally made of casting. Thin-wall parts are not suitable for sand casting; small and medium-sized parts can consider using advanced casting methods: large parts can be cast with sand-shaped. For the general staircase shaft, if the diameter of the stairs is not large, you can use a round stick; if the diameter of each step is large, in order to reduce the amount of material consumption and mechanical processing, it is appropriate to choose a forging rough. Large parts generally choose free forging: small and medium-sized parts can choose mold forging; some small parts can be made into a whole blank.

(3) Production type

For batch production parts, a rough manufacturing method with high accuracy and high productivity should be selected. For example, the casting uses a metal machine modeling or fine casting, and the forging parts are forged and precious; In hours, you should choose a rough manufacturing method with lower accuracy and productivity.

(4) Existing production conditions

To determine the type and manufacturing method of the blank, you must consider specific production conditions, such as the technical level, equipment status, and the possibility of external cooperation.

(5) Fully consider the adoption of new technologies, new processes and new materials.

With the development of mechanical manufacturing technology, the application of new technologies, new processes, and new materials in rough manufacturing has also developed rapidly. Such as precision casting, precision forging, cold squeeze, powder metallurgy and engineering plastics, more and more for machinery. The use of these methods has greatly reduced the amount of processing, and sometimes it can meet the processing requirements without processing, and its economic benefits are very significant. Choose full consideration when choosing wool.

- Min.Order Quantity: 4 Piece/Pieces

- Supply Ability: 100000 Piece/Pieces per Month