I. Process difference

To put it simply, casting refers to the process of melting metal into a liquid that meets certain requirements and pouring it into the mould, and obtaining castings (parts or blanks) with predetermined shape, size and performance after cooling, solidification and finishing.

Forging is a processing method that uses forging machinery to apply pressure to metal billets to produce plastic deformation to obtain forgings with certain mechanical properties, certain shapes and sizes.

The casting hub process is relatively simple and suitable for low-cost mass production; the casting hub has a tight structure, can withstand high stress, and has a higher degree of freedom in modelling design to meet personalised needs.

II. Material difference

Generally speaking, the forging hub is moulded with 6061 aviation aluminum; the casting hub is moulded with civil aluminum A356.2 aluminum alloy mould. The difference between the two materials makes there a significant gap between the product strength, fatigue resistance and safety of the two hubs.

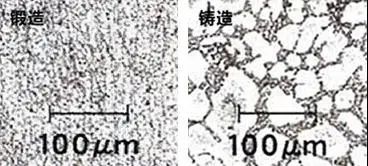

Under the microscope, the detailed structure of the hub is shown, and the forged internal structure is tighter and the hub strength is higher.

III. Differences in appearance

Positive judgement: Due to the process of casting hubs, the drawing angle generally takes 7° to 10°, and the forging hub drawing angle is generally 0° to 3°, so it can be judged intuitively.

Judgement on the back: casting hubs must make back escape material, one is to reduce weight, and the other is to make it convenient to engrave symbols. Forging hubs may not have escape material (there are also special ones, but the escape style will be different)

Sound judgement: The hub made of good aluminum is denser, so the echo of tapping is more crisp. If it is liquid aluminum forging technology, the sound of the hub is the most crisp, and the echo may sometimes last for a few seconds. If you find that the echo is stuffy or there is almost no echo after tapping, it is better to give up.

Hand feel judgement: Forging is thinner than the thickness of the casting rim, all of which are judged by hand feel or weight.

Post time: Jun-02-2023